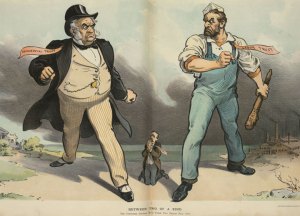

The Source of the Impasse Between Labor and Management

In the course of my more than thirty years in the Welding Industry, both as a welder and an inspector, I have come to believe that the source of the ever-present disconnect between Labor and Management boils down to the different philosophical premises that formulate the standards, beliefs and subsequent actions taken by each.

Management typically exists in an intellectual/ theoretical world of ideas and concepts. I say this with no dismissive or pejorative intent, but the best ideas of an Engineer are exactly that; ideas. Until a welder shows up and brings that idea into the realm of physical reality. Abstractions and cliches pass for deep and insightful in an office setting, not so much in the shop of the field.

Welding, as much as any activity I could think of, is a domain that is anchored deep in absolute physical reality. Imagine a welder building a pipe spool that was a foot and a half too short of its connecting flange on a tank or vessel and then standing back and uttering some phrase like, “think outside the box”. The welder would be laughed off site. Properly so. This is not for lack of intelligence, but a consequence of the philosophical premise involved.

The world of the manager is theoretical, the welder’s world is one of absolutes. And herein lies the problem…

Many in management have fallen into the trap that says that there is no absolute reality, everything is perspective. The more the manager has been educated at the University level, the more this is apt to be the case. Post-Modernism, which is currently the dominant philosophical trend in Academia states exactly that; that there is no reality, only interpretations of reality and no one interpretation is any more valid than any other.

So now we begin to see the cause of the conflict emerge. Using our previous example of the pipe spool being built a foot and a half too short, go ahead and tell yourself that it’s not really too short, that it only appears too short. After all, it’s only a matter of perspective, right?! Now go ahead and open the valve to a line built on this premise and let your product flow. You will find out fast that reality is an absolute that is not to be faked, altered or cheated in any way as you are cleaning up the mess and paying fines and penalties to the appropriate jurisdictions.

The welder understands the absolutism of reality on some level, irrespective of how they may conceptualize the issue. The manager, having been trained in and operating in a theoretical world, may often struggle with this.

Welders often have a stereotypical reputation of being difficult or having “attitudes”, sometimes deservedly so, sometimes not. But maybe what some managers might mistake for “difficult”, or “attitude” may be integrity; the refusal to try to fake or alter the facts of reality. The welder is confined to reality, the manager, not so much.

Ayn Rand once said that “Nature, to be commanded, must first be obeyed.” Good welders implicitly understand this, exceptional welders openly embrace this dynamic.

The next time you have a conflict with a welder, consider asking if this philosophical disconnect is at the root of it. Is this welder just difficult for the sport of it, or does he possibly know something you don’t? If you want to find and keep good welders, you might want to at least consider this question. Only honest and open communication will lead you to the answer. Ask questions and give the welder the professional respect of at least entertaining the possibility that he or she may have something to say worth hearing. You may be pleasantly surprised by what you find.

As always, I hope this has been of some assistance and remember; your work is your signature. What do you want to say with yours?

Glenn Howard Weidman